© 2019 IOP Publishing Ltd

1. Introduction

Since the discovery of fullerenes [1], the family of

nanocarbon allotropes has been studied extensively

due to the carbon–carbon bond versatility [2, 3],

with carbon nanotube (CNT) and graphene being

the most well-known [4, 5]. The superior properties

of these nanocarbon materials such as their large

surface-to-volume ratios, electrical and thermal

transport, tunability of band structure by applied

voltage [6–8], magnetic field [9, 10], and mechanical

strain [11–13], as well as synthesis methods have paved

the way for practical applications in nanoelectronics,

electrochemistry, sensors, and supercapacitors

[14–17]. However, such properties have not been

fully exploited in many potential applications. This is

partly due to the non-uniformity of the synthesized

nanocarbon [18, 19], resulting from the non-

ideal interface between the nanocarbon and other

constituent materials [20–26]. For example, CNT

has long been considered as a promising material to

replace copper in on-chip interconnects as the current

density in copper lines exceeds its current-carrying

capacity [27–30]. In reality, although researchers

have demonstrated CNT vias down to sub-100 nm

dimensions [31–33], the resistance of the CNT vias

is still much larger than that of mainstream copper

interconnects. Such large interconnect resistance is

mainly due to contact resistance between the CNTs

and other conductors [21, 22, 24, 34]. Many efforts

have been devoted to reducing the contact resistance

for carbon-based electron devices [35]. Since both

W Du et al

042005

2D MATER.

© 2019 IOP Publishing Ltd

6

2D Mater.

2DM

2053-1583

10.1088/2053-1583/ab41d3

4

1

16

2D Materials

IOP

23

September

2019

Structures, properties, and applications of CNT-graphene

heterostructures

Wei Du

1

, Zubair Ahmed

2

, Qi Wang

1

, Cui Yu

3

, Zhihong Feng

3

,

6

, Guoyuan Li

1

, Min Zhang

4

,

Changjian Zhou

1

,

6

, Richard Senegor

5

and Cary Y Yang

5

1

School of Microelectronics, South China University of Technology, Guangzhou 510641, People’s Republic of China

2

Department of Electronic and Computer Engineering, The Hong Kong University of Science and Technology, Kowloon, Hong Kong,

People’s Republic of China

3

National Key Laboratory of ASIC, Hebei Semiconductor Research Institute, Shijiazhuang 050051, People’s Republic of China

4

School of Electronic and Computer Engineering, Peking University, Shenzhen 518055, People’s Republic of China

5

Center for Nanostructures, Santa Clara University, Santa Clara, CA, United States of America

6

Authors to whom any correspondence should be addressed.

E-mail: [email protected] and [email protected]

Keywords: graphene, carbon nanotube, heterostructure, interconnect, electron transport, thermal transport

Abstract

Both carbon nanotube (CNT) and graphene exhibit excellent properties and have many potential

applications in integrated circuits, composite materials, thermal management, sensors, energy

storage, and flexible electronics. However, their superior properties are confined to one or two

dimensions, thus limiting their utility in interconnects or thermal interface materials that require a

3D structure for efficient electron and/or phonon transport. It is conceivable that a combined CNT-

graphene structure would provide new opportunities for realizable applications in these and other

fields. In recent years, numerous results on synthesis, structural analyses, theoretical modeling, and

potential applications of various CNT-graphene heterostructures have been reported. In this review,

we summarize the possible structures that can be formed by connecting CNT and graphene. We then

report existing experimental efforts to synthesize the heterostructures based on growth method,

catalyst design, and the resulting properties. Also, theoretical studies on various heterostructures

are reviewed, with the focus on electron and thermal transport within the heterostructure and

across the CNT-graphene interface. Several potential applications are briefly discussed, and a

combined theoretical and experimental approach is proposed with the objective of enhancing the

understanding of the CNT-graphene heterostructure and attaining a realistic assessment of its

feasibility in practical applications.

TOPICAL REVIEW

2019

RECEIVED

20 May 2019

REVISED

20 August 2019

ACCEPTED FOR PUBLICATION

5 September 2019

PUBLISHED

23 September 2019

https://doi.org/10.1088/2053-1583/ab41d3

2D Mater. 6 (2019) 042005

2

W Du et al

graphene and CNT have the same honeycomb

structure, a seamless contact between them appears

possible [36]. A 3D all-carbon structure consisting of

CNT-on-graphene could realize excellent electrical

and thermal conduction in both horizontal and

vertical directions. Such a structure could then serve as

a building block in on-chip interconnects.

In applications that aim to take advantage of

the large surface-to-volume ratio in CNT and gra-

phene, such as electrodes in supercapacitors, batter-

ies, and reactive catalysts [37–39], it is challenging to

prevent the aggregation of the nanocarbons [40, 41].

In contrast, if a heterostructure consisting of verti-

cal CNT arrays and horizontal graphene layers is

formed, a more robust structure is expected to resist

the aggregation tendency while still preserving the

high surface-to-volume ratio [42, 43], electrical and

thermal transport [44, 45], optical and optoelectronic

properties [46], and tunability of band structure by

applied volt age [6–8] and magnetic field [9, 10, 47].

With the objective to fully exploit the extraordi-

nary properties of nanocarbons, researchers in various

disciplines, including electronics [48, 49], material sci-

ence [50], mechanical engineering [51], and chemistry

[52], have explored the possibility of combining these

two most well-known nanocarbon allotropes during

the last decade. Therefore, it is meaningful to review

what has been achieved, and what can be expected in

future studies of the CNT-graphene heterostructure.

This paper is organized as follows. The next sec-

tion describes the basic structures of and synthesis

methods for CNT-graphene heterostructures, fol-

lowed by a review of theoretical studies based on

techniques including first-principle calculations and

molecular dynamics simulations. We then present

various potential applications of the heterostruc-

tures. Finally, we conclude with a discussion of what is

needed to fully optimize the heterostructure for practi-

cal applications.

2. Structures and growth methods

2.1. Structures

To make full use of the structure and properties of the

1D CNT and 2D graphene, various methods have been

proposed to prepare CNT arrays [53], while graphene,

with its 2D planar structure, is usually grown on metal

foils or thin films [54]. Although both show promise

in many applications, it is beneficial to combine them

into a single CNT-graphene heterostructure, which

not only preserves the excellent properties of the

two materials, but also compensates for each other’s

shortcomings to some extent. Generally, CNT grows

along the axial direction, thus forming CNT arrays

vertical or parallel to the substrate. Several possible

models of joining CNTs and graphene are illustrated

in figure 1. A parallel CNT-graphene heterostructure

[55–58] (figure 1(a)) can be obtained by drop-casting

CNT on the transferred graphene, or graphene can

be transferred to cover the CNT network to form a

similar structure but with graphene on top [59]. While

these two structures preserve the 2D structure as in

graphene, it is desirable to form a truly 3D structure by

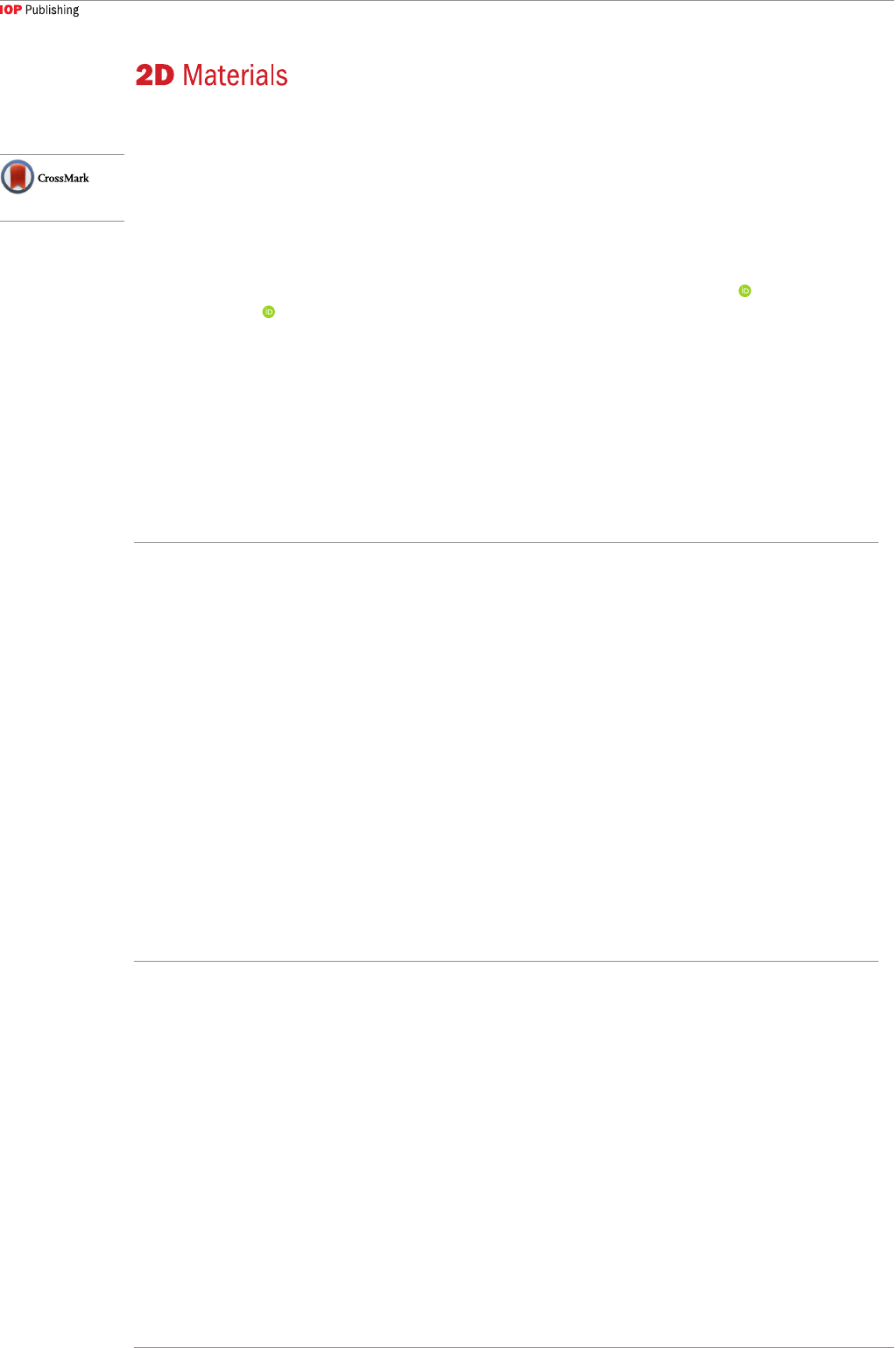

joining vertical CNTs and planar graphene. Figure 1(b)

shows a typical structure with the CNT axis normal

to the graphene plane [42, 60–65], forming a vertical

CNT-graphene heterostructure. In certain cases, the

graphene can be lifted off during the CNT growth, thus

forming a structure as shown in figure 1(c) [66–69].

Recently, several experimental works claimed to obtain

seamless CNT-graphene heterostructures [36, 70]

(figures 1(d) and (e)). Multilayered vertical CNT-

graphene heterostructure was also reported as an all-

carbon pillared structure [71] (figure 1(f)), in which

graphene was used as the platform for CNT growth

and the grown CNTs served as pillars to support

graphene layers. In principle, the seamless junctions

between CNT and graphene can yield a more robust

mechanical structure with enhanced interplanar

electrical and thermal conduction.

In general, compared to the parallel CNT-graphene

heterostructure, the vertical CNT-graphene configu-

ration is more desirable for applications that require

low electrical resistance. Gao [72] compared the resist-

ance of the parallel and vertical CNT-graphene het-

erostructures, and found that the parallel heterostruc-

ture exhibited a contact resistance of 51.9 kΩ, which is

nearly four times the contact resistance of 14 kΩ in the

vertical heterostructure. The difference is likely due to

the unsatur ated π-bonds of edge atoms in the vertical

CNT configuration, giving rise to stronger bonding

with atoms in the graphene layer. Based on the devel-

opment of the different pillared heterostructures,

theoretical and experimental analyses of the CNT-gra-

phene-CNT heterostructure (figure 1(f)) have been

carried out in recent years [52, 71, 72–76].

2.2. Growth methods

As there are many excellent reviews on the growth

of CNT and graphene [53, 77–79], the focus of this

paper is on the growth of the heterostructure itself.

Specifically, we discuss the various parameters for

growth of CNT-graphene heterostructures, including

the overall methodology, catalyst requirement, growth

temperature, and properties of the resulting structure.

2.2.1. Parallel CNT-graphene heterostructures

Parallel CNT-graphene heterostructures are generally

formed using chemical vapor deposition (CVD)

[56, 57, 80]. In such a method, a graphene film is

synthesized first, followed by catalyst deposition on the

graphene and then CNT growth to form the parallel

CNT-graphene heterostructure. For example, using

FeCl

3

solution deposited on graphene as catalyst, CNTs

were formed on the dried sample after the introduction

of argon/hydrogen/acetylene (30/30/5 sccm) at 750 °C

[80]. It was determined that the density and the

quality of the CNTs was related to the concentration

2D Mater. 6 (2019) 042005

3

W Du et al

of the FeCl

3

solution. The density of CNTs can be well

controlled simply by choosing the corresponding

concentration for a targeted density requirement. On

the other hand, the use of the FeCl

3

is avoided in many

cases because of the potentially hazardous waste it

creates. With CNTs as the template, a CNT spider web

was firstly deposited on a copper substrate [56], then a

xylene solution consisting of ferrocene and sulfur was

injected into CNT webs, followed by high-temperature

annealing. The parallel CNT-graphene heterostructure

was then formed with the introduction of a carbon

source, and the CNTs served as nucleation centers

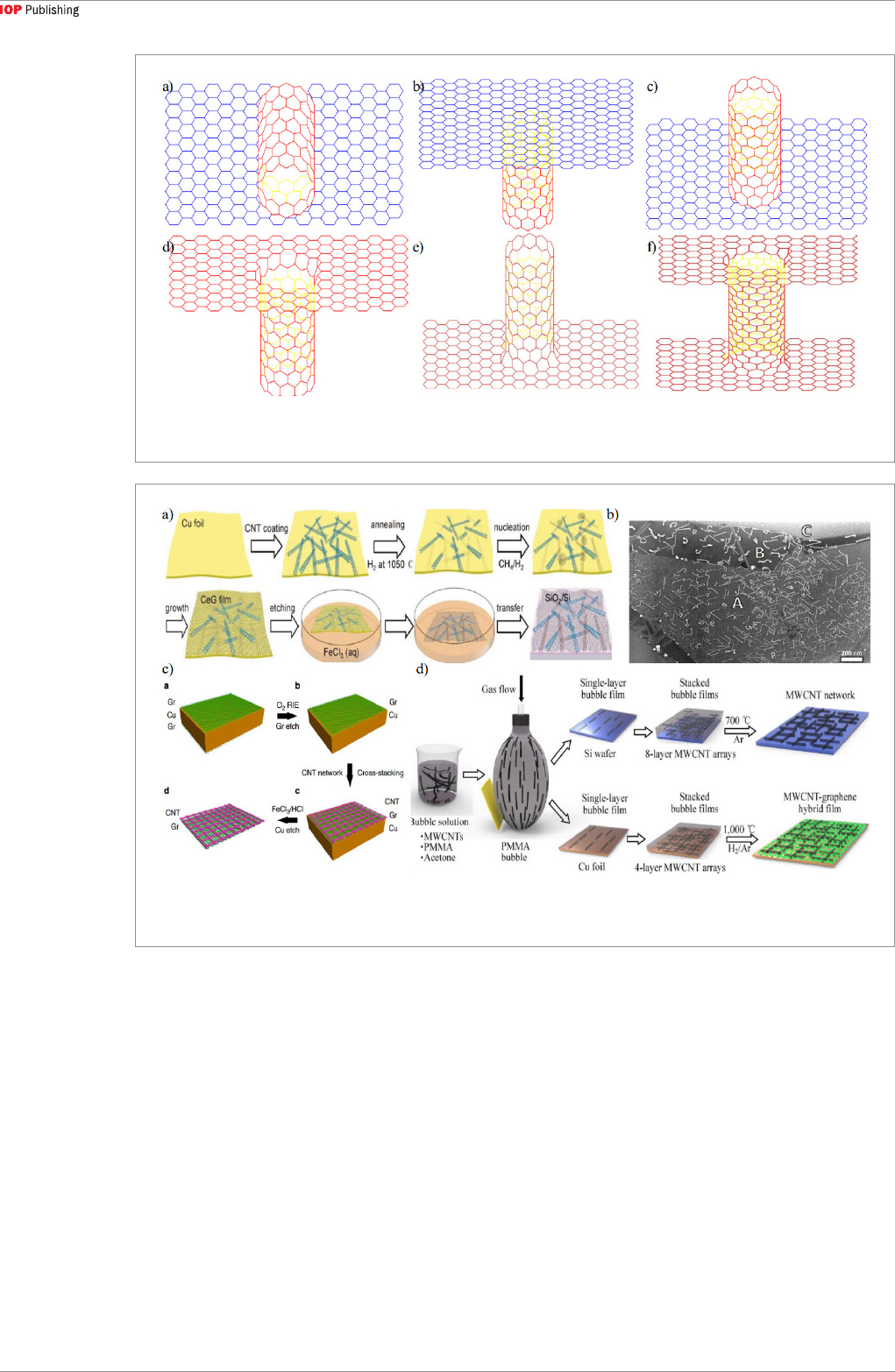

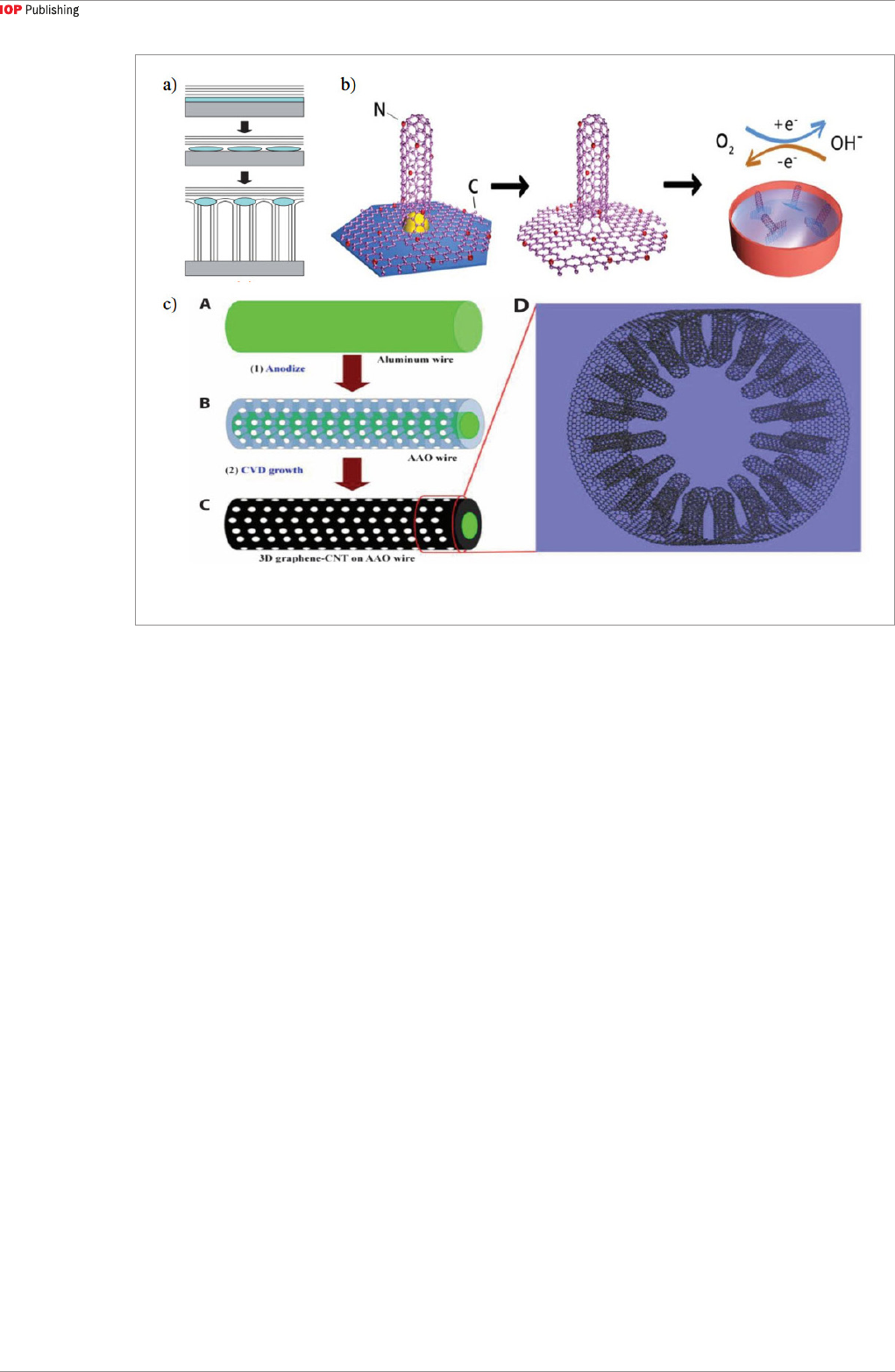

during the graphene growth, as shown in figure 2(a).

This cage-growth method ensures good matching

between CNT network-embroidered graphene film

and graphene, which contributes to the development of

all-carbon devices.

An alternative method used graphene as the

growth template, on which the CNTs were directly

deposited without carbon source gas [57]. It was

found that CNTs in the parallel heterostructure lay

mainly along the armchair axes of the graphene film

(figure 2(b)). To obtain better aligned CNT-graphene

heterostructure, coating the CNTs on graphene was

used, while ensuring that the CNTs and graphene were

firmly connected. Figure 2(c) shows the graphene film

coated with cross-folded CNT networks [81]. After

etching the Cu substrate, a self-standing parallel CNT-

graphene heterostructure was obtained. The CNT-

graphene film obtained by the facile method has ~90%

electron transparency, which is suitable for high-per-

formance electrode applications.

Various methods have been proposed to increase

the CNT density and thus the electrical performance

Figure 1. Schematic illustrations of the (a) parallel CNT-graphene heterostructure, (b) and (c) normal CNT-graphene

heterostructure, (d) and (e) seamless CNT-graphene heterostructure, and (f) CNT-graphene-CNT heterostructure.

Figure 2. Scheme for CNT-graphene parallel heterostructure. (a) Graphene grown by Chemical Vapor deposition using CNTs

as templates [56]. (b) CNTs grown by Chemical Vapor deposition using graphene film as template [57]. (c) Cross-staking CNT

networks coated on the graphene film [81]. (d) By blown bubble method [55].

2D Mater. 6 (2019) 042005

4

W Du et al

of the resultant heterostructure. Wu [55] adopted a

blown bubble method to prepare the aligned CNT

arrays on top of graphene (figure 2(d)). Multiwall

CNTs (MWCNTs) were grown first, and a CNT solu-

tion with PMMA and acetone as the solvent was pre-

pared to form the bubble solution. Aligned CNTs were

obtained due to surface tension of the bubble. The

CNT density was increased by simply repeating the

bubble transferring process. The final high-temper-

ature annealing process could enhance the bonding

between CNT and graphene, which is beneficial for

electrical and thermal applications.

2.2.2. Vertical CNT-graphene heterostructure

In general, CVD [50, 81–88] is the most common

method for synthesizing vertical CNT-graphene

heterostructures, using a two-step process as

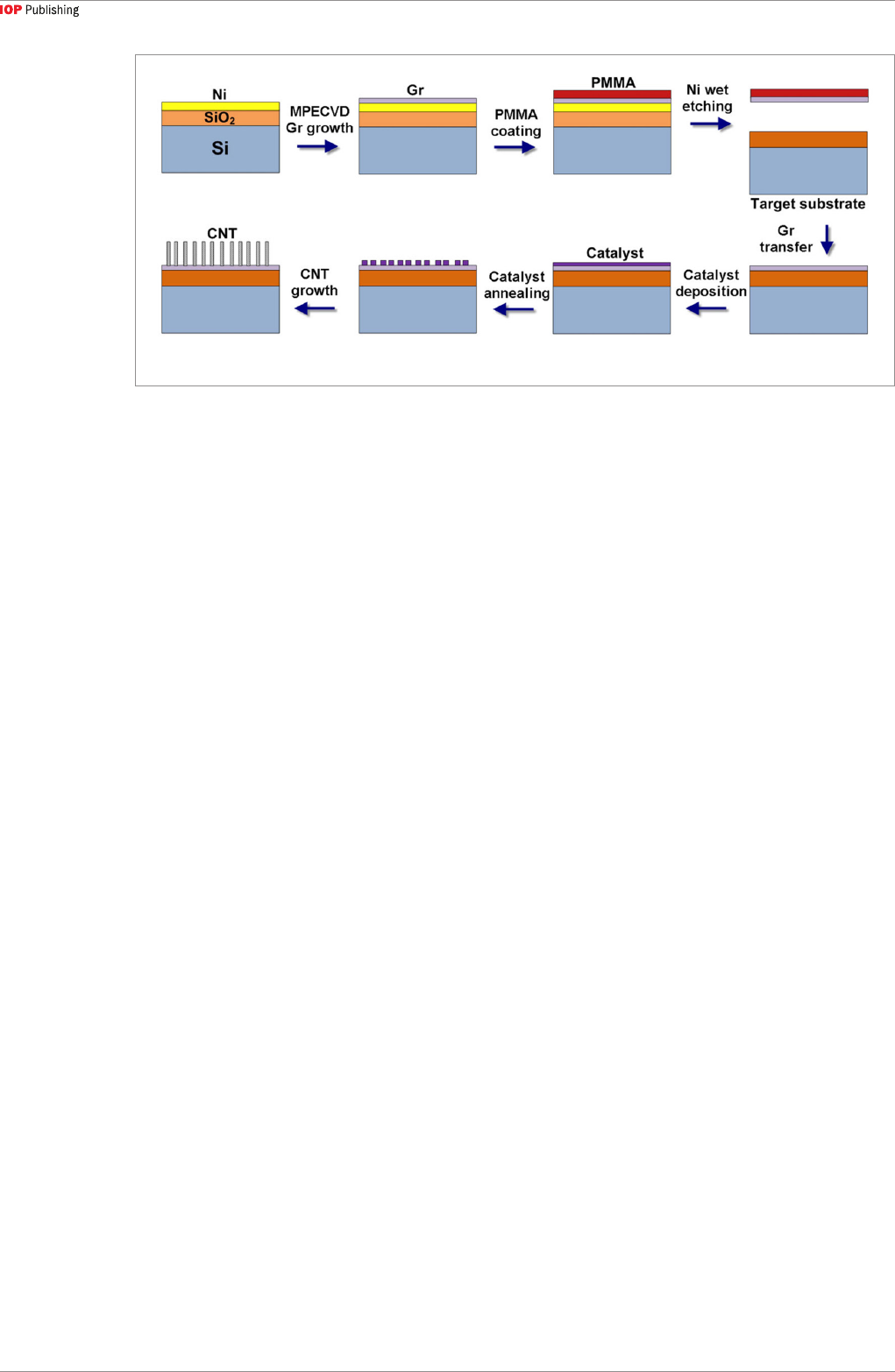

illustrated in figure 3 [89]. First, graphene is grown on

a metal substrate and subsequently transferred onto a

target substrate if needed. Second, the vertical CNT-

graphene heterostructure is synthesized after catalyst

deposition and introduction of a carbon source gas.

There are many factors that affect the growth, and

we will focus on the effects of catalysts, temperature,

and gases on the characteristics of the resulting

heterostructure.

Experiments on the choice of catalyst using differ-

ent thicknesses of Fe or Ni have been carried out [89].

It was found that if the Fe film thickness could be con-

trolled within a range of 0.2 nm to 1 nm, better quality

of CNTs was obtained for thinner films, as confirmed

by Raman analyses. When the Fe film thickness was as

low as 0.5 nm, single-walled CNTs (SWCNTs) were

obtained. Otherwise, MWCNTs resulted whether Fe or

Ni was used as the catalyst [89]. The diameter of the

CNTs is largely affected by the catalyst film thickness.

In addition, the effects of Ni and Fe catalyst on forma-

tion of the CNT-heterostructure are quite different, as

Ni etches graphene during the growth process, leading

to more defects in the final structure. It is worth noting

that the etching of the graphene is expected, because in

the early stages of CNT growth, graphene is a carbon

source in addition to the carbon source gas. And H

2

also plays an important role in the etching of graphene

because of the reaction [63]

(Ni)

nanoparticle

+ C

graphene

+ 2H

2

→ Ni + CH

4

.

The growth temperature and gas feedstock can be

tuned to minimize graphene etching. By using

C

2

H

4

as the carbon source, the Ni catalyst film can form

higher density nanoparticles at 700 °C and the etching

becomes less reactive compared to 800 °C, resulting in

higher density CNTs and less etching of graphene [63].

Apart from graphene etching, catalytic nanopar-

ticles become embedded in the CNT-graphene junc-

tions in some cases, which limits the properties of

the heterostructure. To prevent this effect and form a

seamless CNT-graphene heterostructure, Zhu [36]

deposited a layer of Al

2

O

3

film on the Fe catalyst film

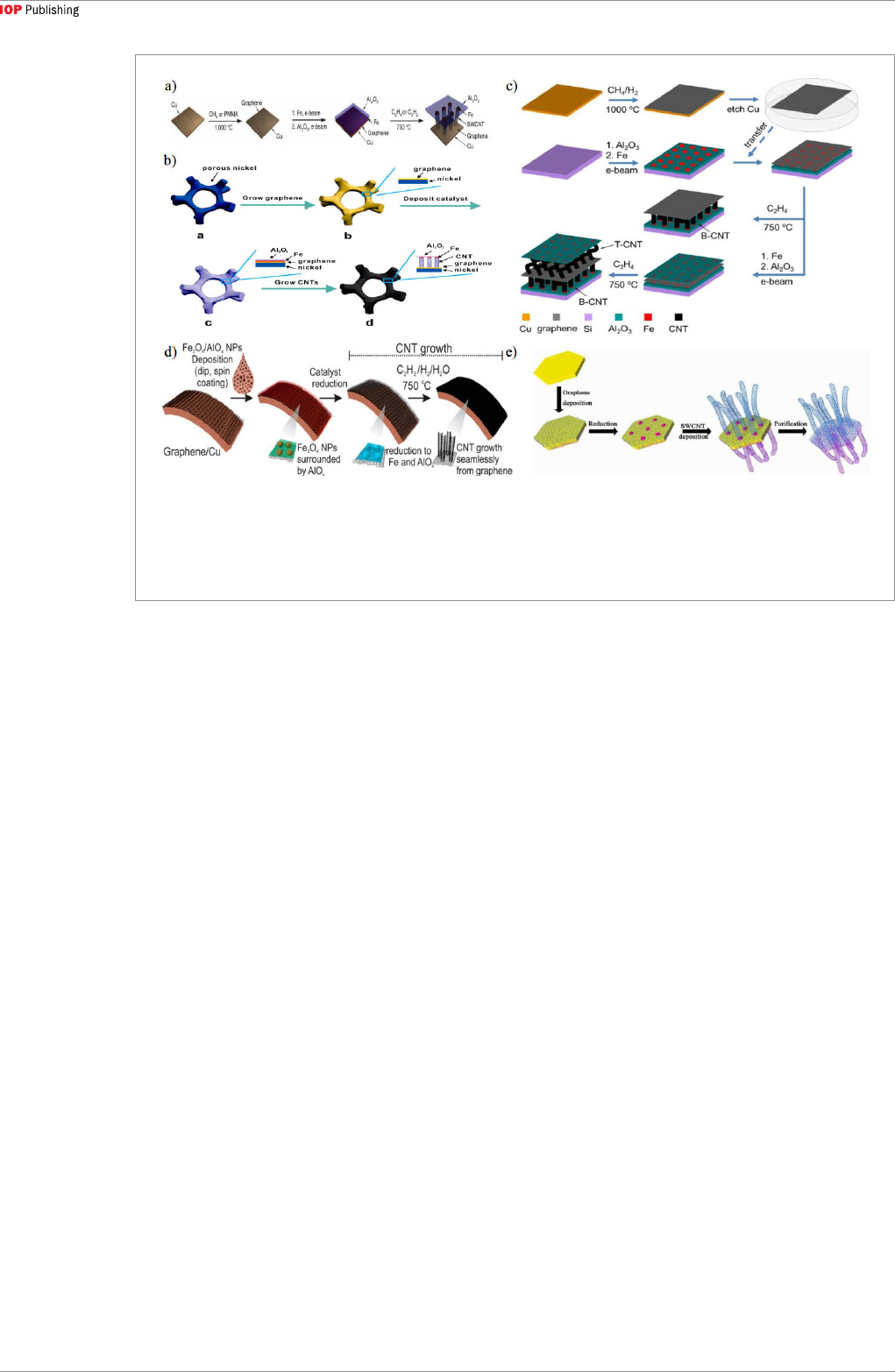

as a floating buffer layer (figure 4(a)). The floating

buffer was designed to transform the bottom growth

of the CNTs into tip growth, thus achieving the goal

of a seamless CNT-graphene heterostructure with

optimal interface properties. Similarly, the hetero-

structure was successfully [87] synthesized on a porous

Ni foam by using the same method but with a better

area utilization ratio of the metal substrate, as shown in

figure 4(b). Inspired by this method, Jiang [77] realized

that CNTs could grow from both sides of graphene,

as shown in figure 4(c). This unique structure has the

potential to be used in energy storage that requires a

high surface-to-volume ratio.

Instead of using solid catalyst films, Rodrigo [70]

spun a solution of Fe

3

O

4

/AlO

x

nanoparticles as the cat-

alyst on the graphene/Cu substrate, which is also appli-

cable to curved substrates. Being exposed to hydrogen

at 750 °C, the catalyst nanoparticles became a mixture

of Fe and Al

2

O

3

. Then a seamless CNT-graphene het-

erostructure was formed via tip growth mechanism,

with the covalent C–C bonds at the CNT-graphene

junction, as shown in figure 4(d). By using Fe catalyst,

SWCNTs can be grown at 950 °C on a FeMgAl layered

double oxide substrate [90], with the process shown

in figure 4(e). Compared to MWCNT, SWCNT arrays

have a higher surface-to-volume ratio and smaller

Figure 3. A two-step process for CNT-graphene heterostructure preparation [89].

2D Mater. 6 (2019) 042005

5

W Du et al

defect density, while forming covalent C–C bond at

the CNT-graphene interface, leading to better elec-

tron transport [90]. The superior properties of the

SWCNT-graphene heterostructure are suitable for

applications as electrodes in high energy density bat-

teries.

In general, all catalyst film thicknesses in the two-

step method are between 1 and 10 nm or thinner to

yield good-quality CNTs. With increase in catalyst film

thickness, graphene can also be formed. Therefore,

CNT and graphene can be grown simultaneously if the

thickness of the catalyst can be controlled within a few

nanometers. Instead of the two-step growth method,

a one-step method is also feasible for forming verti-

cal CNT-graphene heterostructures, thus simplify-

ing the growth process. Kondo [67] deposited differ-

ent thickness of Co film on 5 nm TiN to form a mixed

catalyst. The thickness of the Co catalyst is within a

few nanometers so that both graphene and CNTs can

be synthesized using Co catalyst. With the gas ratio

of acetylene to argon being 1:9, graphene films were

formed first, then the Co catalyst film dewetted to

form nanoparticles, followed by CNT growth at 510

°C using tip-growth mode and resulting in a vertical

CNT-graphene heterostructure on a silica substrate

(figure 5(a)). It was found that increased Co thickness

resulted in increased graphene thickness.

Ni/TiN was also reported as a catalyst to synthesize

CNTs and graphene [68]. Without conventional argon

pretreatment, Jousseaume [68] used C

3

H

6

as the car-

bon source gas rather than traditional C

2

H

2

or CH

4

,

and prepared a vertical CNT-graphene heterostruc-

ture at 400 °C using bottom-growth mode. The lower

temperature ensures compatibility with chip manu-

facturing processes for the vertical CNT-graphene

heterostructure to serve as part of an on-chip inter-

connect network. Furthermore, using FeMoMgAl lay-

ered double hydroxides as catalyst, a nitrogen-doped

CNT-graphene heterostructure has also been achieved

by the one-step method [91]. The schematic of the

growth process is shown in figure 5(b). The specific

surface area of the structure reached 812.9 m

2

g

−1

and

the electrical conductivity was as high as 53.8 S cm

−1

.

In addition, the structure had excellent bifunctional

oxygen electrode activity for both oxygen reduction

reaction and oxygen evolution reaction, which offers

possibility to be a bifunctional electrocatalyst in metal-

free devices.

Seamless heterostructures can also be obtained by

the one-step method [92]. A typical example is shown

in figure 5(c). First, an aluminum wire was exposed

to 0.3M oxalic acid solution at 40 V and 3 °C so that

the external surface could be turned into anodized

aluminum oxide. Then without catalyst, CNTs were

seamlessly surrounded by a cylindrical graphene layer

using CVD. In general, the key in the one-step growth

is the proper choice of catalyst (material and thickness)

and temperature to form the two constituent nanocar-

bon materials sequentially or simultaneously.

It is expected that the seamless heterostructure

shown in figures 2(d)–(e) can provide superior elec-

tronic and thermal transport properties through the

CNT-graphene junction as well as improved mechani-

cal stability. However, there is still little evidence that

the fabricated vertical structure possesses a seamless

connection. Several proposed connection topologies

Figure 4. Scheme for CNT-graphene vertical heterostructure. (a) Synthesis of CNT carpets directly from graphene by adding a

layer of Al

2

O

3

film on Cu substrate [36]. (b) Synthesis of seamless CNT-graphene heterostructure by adding a layer of Al

2

O

3

film on

porous Ni substrate [87]. (c) CNTs grown from both sides of graphene using supporting layer: Al

2

O

3

films [76]. (d) Using solution

of Fe

3

O

4

/AlO

x

nanoparticles as catalyst [70]. (e) Growing seamless SWCNT-graphene heterostructure on FeMgAl layered double

oxide substrate [90].

2D Mater. 6 (2019) 042005

6

W Du et al

between CNT and graphene are presented in the next

section along with first-principle calculations. How-

ever, high-resolution transmission electron micros-

copy is needed to show experimentally how the carbon

atoms are connected at the CNT-graphene junction.

We hope that with more advanced characterization

techniques, the atomic arrangement at the junction

can be identified, and provide an experimentally con-

firmed structure for theoretical calculations.

3. Theoretical Studies of CNT-Graphene

Heterostructures

Both CNT and graphene have extraordinary electronic

transport properties, mechanical strength, and

thermal conductivity. Until now, various theoretical

methods have been employed to study the properties

of CNT-graphene heterostructure, specifically to

simulate seamless CNT-graphene heterostructures.

In principle, there can be numerous geometrical

configurations for both parallel and vertical CNT-

graphene heterostructures, considering the various

CNT chiralities, the number of walls in a CNT, the

bonding type between CNT and graphene that could

be van der Waals or covalent. Thus, it would not be

practical to list all the possibilities of CNT-graphene

heterostructures. Those that have been studied are

constrained partly by the computational resources and

the difficulty in establishing a stable junction between a

CNT and graphene. Nevertheless, there are interesting

properties revealed by various theoretical studies,

though most remain unverified by experiment.

3.1. Parallel CNT-graphene heterostructure

As the parallel CNT-graphene heterostructure is

mainly used for electrodes or all-carbon transistors,

most theoretical studies have focused on its electronic

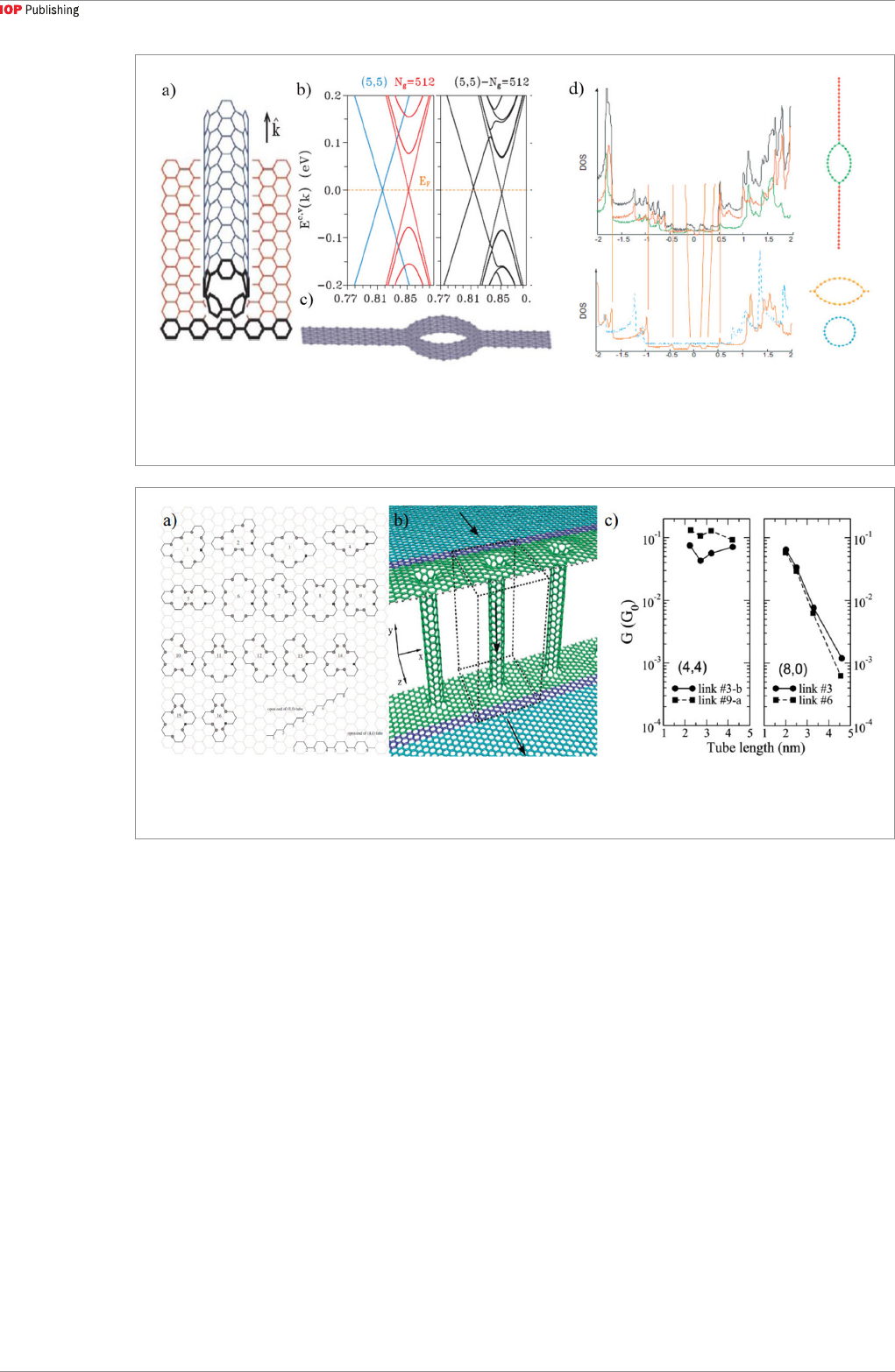

properties [93–95]. Ho [93] studied the electronic

structures of a non-chiral (armchair or zigzag type)

CNT positioned flat on the underlying graphene,

as shown in figure 6(a). The exact position of CNT

is optimized using the Lennard-Jones interatomic

potential, and the interlayer distance between CNT

and graphene is around 3.1 Å–3.2 Å, implying that

the bonding is van der Waals type. Compared to

pristine CNT and graphene, the band structure of

the heterostructure exhibits typical coupling effects

between CNT and graphene, resulting in extra band-

edge states at the intersecting linear bands, as shown

in figure 6(b). The coupling effect can be further

modulated by rotating the CNT relative to the in-

registry position, but it generally weakens as the CNT

diameter and the interfacial distance increases. One

interesting phenomenon is the induced non-zero

bandgap for pristine metallic (3m, 0) CNT due to

coupling to the graphene, suggesting that even metallic

CNT can be used for transistors if the CNT diameter

is small and graphene is used as an underlying

substrate. Similarly, Cook [94] calculated the charge

redistribution between graphene and semiconducting

(8,0) and (10,0) CNTs, and reported a very low

Schottky barrier height between CNT and graphene.

This is qualitatively verified by experimental results of

Chai [96, 97], who applied graphitic interfacial contact

layer to improve the CNT transistor properties, and of

Figure 5. (a) Scheme of one-step method process [68]. (b) Process of the nitrogen-doped graphene/carbon nanotube hybrids

growth [91]. (c) Schematic of radially aligned CNTs growth process [92].

2D Mater. 6 (2019) 042005

7

W Du et al

Ganggavarapu [96, 97], who achieved ohmic contact

between CNT and few-layer graphene.

A seamless parallel CNT-graphene heterostruc-

ture with a (12,0) CNT covalently bonded to one or

more graphene nanoribbons with the same width as

the CNT length has been proposed [98–100]. A com-

mon feature of these structures is the sp

3

-like bonding

at the interface between CNT and graphene. Artyukh

[100] studied the structure where the atoms at the

edge of the two graphene nanoribbons are directly

connected to the CNT wall, as shown in figure 6(c).

Compared to pristine CNT or graphene, the den-

sity of states (DOS) of the heterostructure exhibits

some similar Van Hove peaks, and resemble those in

hydrogenated CNT, as shown in figure 6(d). In terms

of mechanical strength, the heterostructure exhibits

much higher Young’s modulus due to the sp

3

bonds

present at the interface [100].

3.2. Vertical CNT-graphene heterostructure

Vertical CNT-graphene heterostructures have

potential applications in many fields such as

electrodes, interconnects, transistors, catalyst, and

thermal interface materials. Thus, the electronic and

thermal transport properties are of much interest for

these applications. In this sub-section, we focus mainly

on the properties of modeled seamless vertical CNT-

graphene heterostructures to examine its electronic

and thermal transport properties.

To form a seamless CNT-graphene heterostructure,

a least-square method is utilized to achieve C–C bond-

lengths or bond-angles as close as possible to those of

the ideal case [101, 102]. Moreover, Euler’s theorem is

utilized to select the polygons for the contact stitching

process [101–106]. Figure 7(a) shows the possible con-

nections that the eight open bonds of a (4,4) CNT or (8,

0) CNT can form with the underlying graphene sheet

[101]. Many theoretical calculations have adopted the

same rules to form seamless CNT-graphene hetero-

structures [71, 107]. After identifying the bond contact

spots on the graphene surface and the CNT, molecular

dynamic simulations are performed to minimize the

total binding energy of the heterostructure. For struc-

ture relaxation, a full quantum mechanical optim-

Figure 6. (a) Parallel CNT-graphene heterostructure with Van der Waals bond between CNT and graphene [93]. (b) Band

structures of the CNT, graphene, and coupled CNT-graphene heterostructure [93]. (c) Parallel CNT-graphene heterostructure with

covalent bond between the CNT and graphene nanoribbons at the two sides [100]. (d) Theoretical density of states (DOS) of the

covalent bonded CNT-graphene heterostructure, the DOS of a hydrogenated CNT is plotted in the lower panel as a reference [100].

Figure 7. (a) Possible ways to seamlessly connecting (4,4) or (8,0) CNT with graphene [101]. (b) Graphene-CNT-graphene

heterostructure used to calculate the transmission coefficient, with the arrows showing the electron transport directions [49].

(c) Deduced conductance of the heterostructure with different CNT type and tube length [49].

2D Mater. 6 (2019) 042005

8

W Du et al

ization including force-field relaxation of the nuclei

as well as the electrons is necessary. However, such

optim ization requires prohibitive amount of time and

computational resources [108]. Therefore, another

approach is employed to achieve force-field conv-

ergence using classical molecular dynamics approach,

which neglects electron interactions [89, 109, 110]. The

advantage of such an approach is drastically reduced

computational time, albeit with less accuracy of the

final optimized structure.

3.2.1. Electronic transport properties

With the optimized heterostructure, one can perform

first-principle calculations to obtain electronic

properties such as band structure, transmission

coefficient, DOS, and conductance. Matsumoto [83]

used a tight-binding method to study various (6,6)

CNT-graphene heterostructures, including CNT with

open tip or capped, and CNT sandwiched between two

graphene layers similar to that in figure 1(f). The total

energy minimization method is adopted to optimize

the geometries using the tight-binding method.

Although the (6,6) CNT is metallic, sizable direct

bandgaps of 0.27 eV and 0.51 eV were predicted for

the open and capped CNT-graphene heterostructures,

respectively. An even larger bandgap was predicted for

the sandwiched heterostructure. Another interesting

structure proposed by Mao [111] also showed a similar

effect that the metallic (5,5) CNT was transformed

into a semiconductor with a bandgap of 0.2 eV.

Strictly speaking, this structure is not a seamless

CNT-graphene heterostructure, because the CNT

is inserted into the graphene and the two ends of the

CNT are connected to the graphene sheets through a

hole on each. Nevertheless, a covalent bond is formed

between each atom at the graphene hole edge and

an atom on the CNT sidewall. This strong coupling

results in a bandgap in the metallic (5,5) CNT. In

contrast, the original bandgap of 0.65 eV vanishes for

a semiconducting (8,0) CNT, because of the induced

impurity states by the sp

3

-like hybridization between

the CNT and the holed graphene. Thus, one may

conclude from the above theoretical study that the

pristine CNT bandgap can be changed due to the

strong covalent bond formed at the CNT-graphene

interface.

Since the tight-binding method could not capture

the junction-induced band offset between CNT and

graphene [83], a first-principle calculation was per-

formed by Frederico [49] to study the electronic trans-

port properties of the (4,4) and (8,0) CNT-graphene

heterostructures. For the metallic (4,4) CNT-graphene

heterostructures, two kinds of symmetrical connec-

tions containing six heptagonal rings at the interface

(No. 3 and No. 9 in figure 7(a)) were adopted. The unit

cell of the periodic 3D seamless heterostructure shown

in figure 7(b) was constructed for electronic transport

calculations using the non-equilibrium Green’s func-

tion (NEGF) method, and the current flow is through

the CNT-graphene junction and the CNT itself. The

calculated transmission coefficient was between 0.01

and 1 and shows a weak dependence on the CNT

length in the range of 2.2–4.2 nm, indicating a clear

ballistic transport characteristic of the (4,4) metal-

lic CNT-graphene heterostructure. The conductance

deduced from the transmission curves also shows a

similar weak dependence on CNT length for metallic

CNTs as shown in figure 7(c). On the other hand, the

conductance shows strong dependence on the contact

structure, with the No. 9 contact structure exhibiting

a higher transmission and conductance than the No.

3 case. In contrast, the conductance of the semicon-

ducting (8,0) CNT-graphene heterostructure shows

a strong dependence on the CNT length and weak

dependence on the contact structure. Another interest-

ing point for the (8,0) CNT-graphene heterostructure

is that a relatively large conductance is predicted for

the heterostructure with a small CNT length of 2 nm

(figure 7(c)), showing the effect of tunneling. Although

the study reveals some interesting electronic transport

properties of the CNT-graphene heterostructure, their

calculation cannot ascertain the exact contribution of

the CNT-graphene junction to the total conductance.

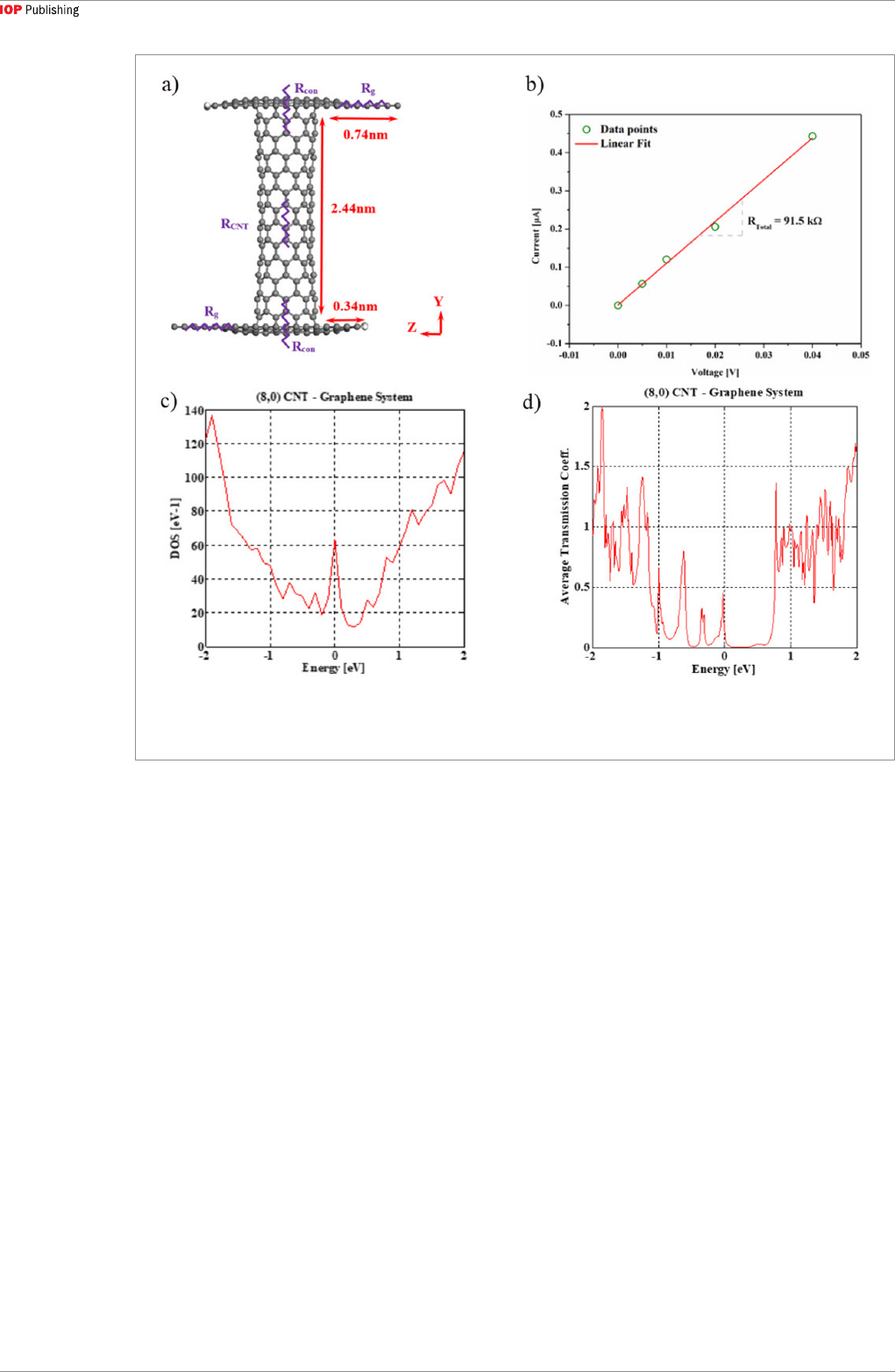

To better understand the CNT-graphene contact

properties, we have performed calculations on a two-

point structure with the NEGF method. To extract the

CNT-graphene contact resistance, graphene resistance,

and CNT resistance, we calculate the current–voltage

(I–V) characteristics of the graphene-CNT-graphene

heterostructure shown in figure 8(a). Toward this end,

we first compute the resistance of a graphene sheet for

different lengths, which turns out to be 6.45 kΩ and

independent of length, confirming ballistic transport.

This result also serves as a validation of the calcul-

ation method. A typical I–V curve for the complete

two-point structure is shown in figure 8(b). The total

resistance is found to be 91.5 kΩ for the heterostructure

with a 2.44 nm long (8,0) CNT. The linear I–V behavior

indicates ohmic conduction across the CNT-graphene

junction and possibly along the CNT as well. Further-

more, we have also verified the previous study that

semiconducting CNTs when contacted with graphene

leads to metallic behavior. The DOS and the transmis-

sion coefficients of the (8,0) CNT-graphene hetero-

structure are shown in figures 8(c) and (d), respectively.

A finite DOS exists at the Fermi-level (located at 0 eV),

representative of the metallic nature of the CNT. The

transmission coefficient shown in figure 8(d) also sug-

gests that transmission indeed occurs at the Fermi-level

because of the available states.

3.2.2. Thermal transport properties

Both CNT and graphene possess outstanding

intrinsic thermal conductivity, but the high thermal

conductivity is only achievable along the CNT length

and in-plane directions in graphene. Vertical CNT

arrays have been considered as a good thermal interface

material (TIM) for its high thermal conductivity along

2D Mater. 6 (2019) 042005

9

W Du et al

its length [112]. However, the interface between the

CNT and the substrate constitutes much of the thermal

resistance, which limits the overall performance

of the thermal interfacial layer. Recently, many

theoretical works have studied the seamless 3D CNT-

graphene heterostructure for its superior thermal

transport properties [74, 75, 113]. The heat flow in

the 3D seamless CNT-graphene heterostructure was

determined to be analogous to current flow [75].

Varshney [75] compared the thermal conduc-

tivity k of the heterostructure with an eight-layer

graphite and a pure (6, 6) CNT. The in-plane thermal

conductivity k

//

of the heterostructure is inferior to

that of an eight-layer graphite, and it increases lin-

early with the distance between adjacent CNTs in the

heterostructure. This can be due to the presence of

less scattering sites for a larger CNT-CNT distance.

The out-of-plane thermal conductivity k

⊥

follows

a similar trend that a larger CNT length results in

a larger k

⊥

. While CNT-CNT distance affects the

overall cross-sectional area of the heterostructure,

the CNT length determines the phonon scattering

length between the two CNT-graphene junctions

separated by one vertical CNT. In general, the k

//

is

much higher than the k

⊥

. For example, the k

//

and k

⊥

are 9.6 W (m K)

−1

and 2.25 W (m K)

−1

, respectively,

for a heterostructure with a CNT-CNT distance of 9

Å. Thus, the two factors must be optim ized to obtain

an overall high k in both directions for practical

applications.

Chen [74] compared k

⊥

of a seamless (6,6) CNT-

graphene heterostructure with the pristine graphene,

and found that the former is at least one order of mag-

nitude larger than the latter. k

⊥

increases with increas-

ing CNT densities, and it reaches about 100 W (m K)

−1

when the density of CNT is about 10%. For efficient

cooling of a hot surface, the heterostructure could

be immersed into a liquid to speed up heat dissipa-

tion [114]. To identify the contribution of the CNT-

graphene junction to the total thermal resistance, Shi

[115] analyzed the temperature profile throughout

the heterostructure, and found that the temperature

jump at the junction contributed to most of the total

thermal resistance. The calculated covalent CNT-gra-

phene junction resistance of 4.1 × 10

−11

m

2

K W

−1

~ 7.2 × 10

−11

m

2

K W

−1

is much lower than those of

other thermal interface materials. On the other hand,

if CNT is weakly connected to the graphene by van der

Waals bond, the calculated junction resistance surged

up to 4 × 10

−8

m

2

K W

−1

, clearly suggesting seamless

covalent bonding between CNT and graphene facili-

tates phonon transport from in-plane direction to out-

Figure 8. (a) Graphene-CNT-graphene heterostructure used for I–V calculations. (b) I–V curve of the graphene-CNT-graphene

heterostructure. (c) DOS and (d) transmission coefficients of the (8,0) CNT graphene system, showing finite DOS and transmission

at Fermi-level (0 eV).

2D Mater. 6 (2019) 042005

10

W Du et al

of-plane direction. A practical application was con-

sidered by Bao [116], who studied the CNT-graphene

heterostructure for heat dissipation from a silicon

substrate. Compared to the CNT-silicon interface, the

insertion of a graphene layer between CNT and silicon

improved the thermal conductance by more than 40%

[116]. Although most of the theoretical study con-

structed similar seamless CNT-graphene structures as

described above, Zhang [113] proposed a novel struc-

ture with a transition cone area between the vertical

CNT and the parallel graphene so that the contact area

could be much larger than the CNT area itself. Com-

pared to the normal CNT-graphene heterostructure,

the proposed structure exhibited an improved thermal

conductance, which even outperformed the pristine

20 Å-diameter CNT if the cone radius reaches 40 Å.

These results suggest alternative ways to construct the

CNT-graphene heterostructure, which can be exper-

imentally realized [113].

As alluded in section 2, MWCNTs are quite com-

mon in grown CNT-graphene heterostructures, yet

few theoretical studies on their transport properties

exist, partly due to the computation resources require-

ment to construct and calculate these complex systems.

In terms of the MWCNT–MWCNT contact where

van der Waals bonds are formed between the carbon

atoms at the outer walls, Varshney [117] stressed the

importance of effective contact area which is affected

by diameter, the number of walls, and the curvature

effect in determining the thermal transfer rate across

the contact area. However, there is no reported study

of the seamless MWCNT-graphene heterostructure to

date. With proper structure construction schemes and

powerful computation resources, the more complex

MWCNT-graphene heterostructure could conceiv-

ably reveal new information for comparison with

experiment.

Even though the synthesized heterostructures

are still quite different from the theoretical model

structures, the introduction of the heterostructure is

motivated largely by applications requiring better elec-

tronic and/or thermal transport properties and larger

surface to volume ratio, which cannot be obtained with

only one form of nanocarbon mat erial. As discussed in

the next section, there are potential applications that

show superior properties of the heterostructure. More

studies are needed to relate the measured properties

of micro or macroscale heterostructures to theor etical

predictions based on a single nanoscale CNT-graphene

junction.

4. Potential applications

Due to the excellent properties of graphene and CNTs,

CNT-graphene heterostructures have been proposed

as electrodes, catalysts, as well as materials for hydrogen

storage and interconnects. In this section, examples are

given stressing the advantages of using CNT-graphene

heterostructures for such applications.

4.1. Electrodes

For electrodes, a large and efficient conducting area

is the key parameter. The large conducting surface of

graphene makes it an attractive candidate. However,

because of the aggregation of graphene, electrodes

composed of graphene alone would not be the optimal

choice. Considering the electrical conductivity of

CNTs, the combination of vertically aligned CNTs on

graphene holds great promise as a superior electrode

The CNT-graphene electrode, also called all-carbon

electrode, has more effective conducting surface

than graphene while retaining its high mechanical

flexibility, resulting in larger electron transfer capacity

[65]. In addition, the resistance of the CNT-graphene

heterostructure is smaller than that of the graphene

[72], which can also enhance electronic transmission.

Thus, CNT-graphene electrode can be a great

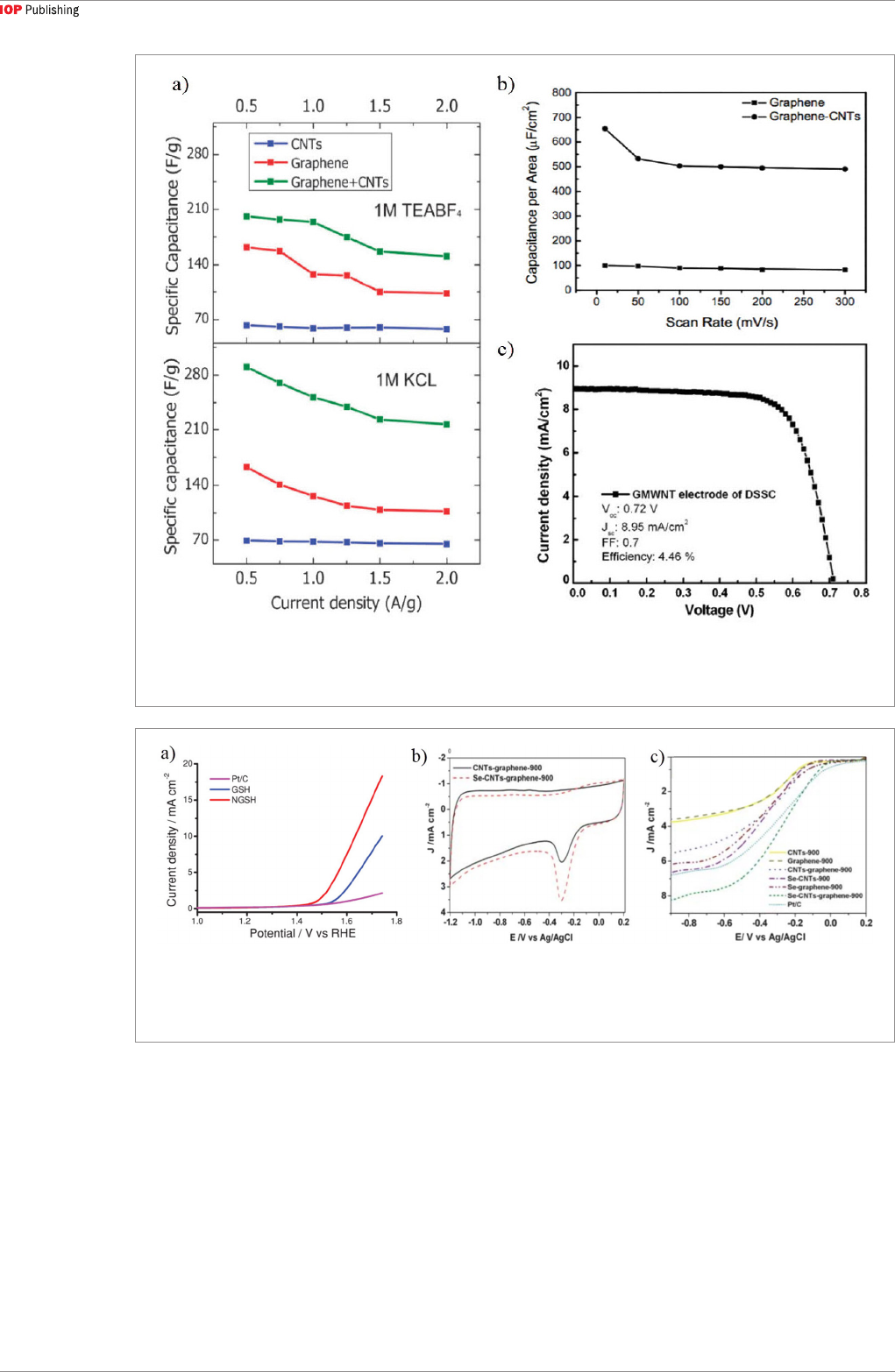

candidate for supercapacitors [42, 52, 118]. Using

parallel CNT-graphene heterostructure as electrodes

[118], a supercapacitor yielded a specific capacitance

of 290.4 F·g

−1

. Figure 9(a) shows the comparison of

specific capacitances of CNT, graphene, graphene/

CNT composite supercapacitors at different charging

current densities, which indicates the superior

performance of the composite supercapacitor. Using

vertical CNT-graphene heterostructure, a high-

performance supercapacitor has been fabricated with

a capacitance of 385 F·g

−1

at a scan rate of 10 mV·s

−1

in 6M KOH solution, with high electrochemical

stability [52]. Another supercapacitor was reported

to exhibit a capacitance of 653.7 µF cm

−2

at 10 mV

s

−1

, and the capacitance of the heterostructure is

higher than that of graphene, as shown in figure 9(b)

[42]. Besides supercapacitors, the CNT-graphene

electrode can also be applied to solar cell. Because

of the larger conducting surface, the dye-sensitized

solar cell showed a fill factor of 0.7 by using a CNT-

graphene heterostructure as the electrode, as shown in

figure 9(c) [60]. Thus, the enhanced effective surface

area and low resistance can create immense potential

for CNT-graphene electrode in supercapacitors or

solar cells, which are renewable and pollution-free

energy storage devices.

4.2. Catalysts

In recent years, CNT-graphene heterostructure has

also been studied as potential metal-free catalyst [91,

119, 120]. By using the one-step method, SWCNTs and

graphene can grow simultaneously on a graphene oxide

(GO) substrate. By in situ doping in the growth process,

a new N-doped graphene/SWCNT hybrid (NGSH)

material can be obtained [91]. Figure 10(a) shows

that N-doped vertical CNT-graphene heterostructure

electrode has higher current density than vertical Pt/C

electrode [91]. Because SWCNTs have higher surface-

to-volume ratio, this NGSH structure possessed a large

specific surface area of 812.9 m

2

g

−1

and high electrical

conductivity of 53.8 S cm

−1

. It turned out that the

hybrid structure was a high-performance and low-

2D Mater. 6 (2019) 042005

11

W Du et al

cost catalyst for both oxygen reduction reaction and

oxygen evolution reaction. Its high oxygen reduction

reaction activity was even better than the commercial

20 wt% Pt/C catalysts because of its better durability

and low resistance [91]. Apart from N-doped CNT-

graphene heterostructure [91, 119], Se-doped CNT-

graphene heterostructure also showed excellent

electrocatalytic activity [120]. Figures 10(b) and (c)

show that the Se-CNTs-graphene heterostructure has

the lowest resistance. Thus, using novel doping and

growth methods can lead to functionalizing metal-free

catalysts using CNT-graphene heterostructures in the

future.

4.3. Hydrogen storage

It is known that hydrogen can be an energy source, but

its storage capacity is low due to the van der Waals force

between hydrogen molecules and the size of the metal

container. A vertical CNT-graphene heterostructure

can offer an alternative to store hydrogen, as its pore

size and surface area can be adjusted by varying the

growth process parameters. Theoretical study was

conducted and showed that this structure can be

effective in increasing storage capacity [71]. When

doped with lithium cations, this structure yielded

41 g of H

2

/L [71], close to the volumetric requirement

of United States Department of Energy for mobile

Figure 9. (a) Comparison of specific capacitance of CNT, graphene and parallel CNT-graphene heterostructure supercapacitors at

different charging current densities [118]. (b) Capacitance of vertical CNT-graphene heterostructure and graphene at scan rates of

10–300 mV s

−1

[42]. (c) Current density versus voltage behavior of dye-sensitized solar cell with a CNT-graphene electrode [60].

Figure 10. (a) Oxide evolution reduction current density of Pt/C, CNT-graphene and N-doped CNT-graphene electrodes in

0.1 mol l

−1

KOH solution at 5 mV s

−1

[91]. (b) Cyclic voltammetry curves of CNT-graphene heterostructure before and after doping

with Se [120]. (c) Linear sweep voltammetry curves for CNT, graphene and CNT-graphene heterostructure before and after doping

with Se [120].

2D Mater. 6 (2019) 042005

12

W Du et al

applications, which is 45 g of H

2

/L. A simulation of the

stacking of the vertical CNT-graphene heterostructure

for hydrogen storage is depicted in figure 11(a). Thus,

successful fabrication of the stacked CNT-graphene

heterostructure can lead to a new hydrogen storage

device in the future.

4.4. Interconnects

Continuous downward scaling in chip manufacturing

has become a major challenge for on-chip

interconnects. Due to electromigration challenges,

on-chip Cu interconnect linewidth can no longer

be reduced further in current technology nodes.

Because of their high current capacity and superior

transport properties, graphene [121, 122] and CNTs

[33] have become potential candidates to replace Cu

interconnects. However, the contact resistance between

CNTs and conventional metal is a major challenge

in functionalizing CNT vias [33]. Therefore, an all-

carbon interconnect network consisting of vertical

CNTs on horizontal graphene could mitigate the

contact resistance challenge. Although the contact

between CNTs and graphene can be refined to yield low

resistance and variability, the contact resistivity can only

be low as ~10

−5

Ω cm

2

[66], which is still high. Further,

to facilitate the proper chip operation, CNTs must be

grown on graphene at temperatures compatible to chip

manufacturing, such as 550 °C [48], 510 °C [67] and

400 °C [68]. A schematic diagram for using CNTs and

graphene as interconnects is shown in figure 11(b). The

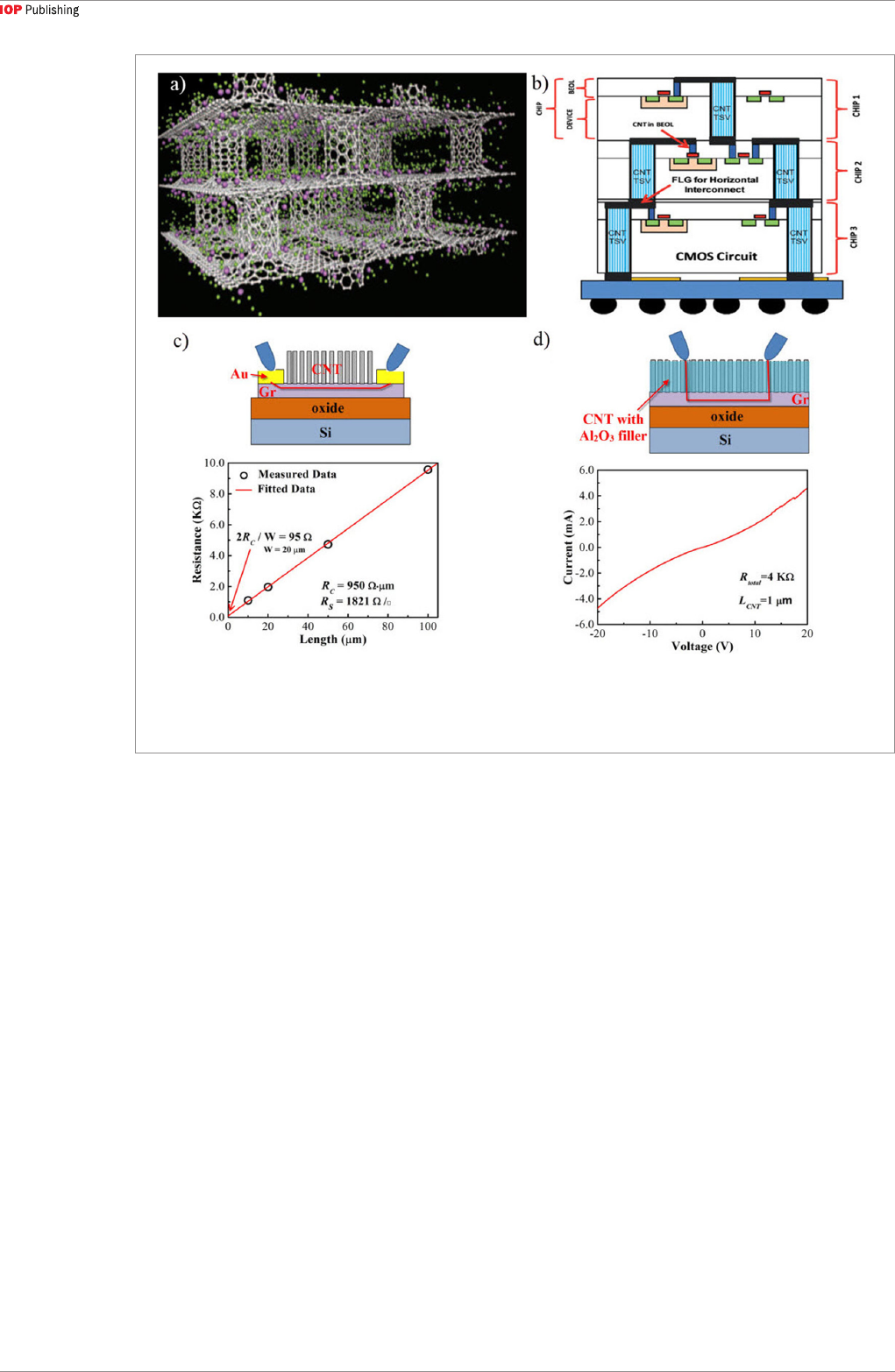

results in figures 11(c) and (d) suggest that conduction

path does exist in a 3D CNT-graphene heterostructure.

However, contact resistance still remains the critical

challenge in its implementation [89].

5. Summary and conclusions

Structures, growth, properties, and potential

applications of various CNT-graphene hetero-

structures have been reviewed, with emphasis on

targeting a specific performance enhancement for

a given application. For a parallel CNT-graphene

heterostructure, where the CNT axis is parallel

to the graphene plane, the main advantages are

enhanced mechanical strength and increase in

electrical conduction paths, providing a suitable

candidate material for flexible electronics and all-

carbon transistors. For a vertical CNT-graphene

heterostructure, a covalently bonded seamless CNT-

graphene junction has been proposed to reduce the

electrical and/or thermal contact resistance due to its

superior electron and phonon transport properties.

Figure 11. (a) Simulated Li-doped vertical CNT-graphene heterostructure [71]. Green for hydrogen molecules and purple for

lithium atoms. (b) Schematic of vertical CNT-graphene heterostructures as interconnects in CMOS circuit [48]. (c) A schematic of

the electrical measurement and resistance versus graphene length behavior after CNT growth [89]. (d) Schematic of the electrical

measurement and I–V characteristics of the vertical CNT-graphene heterostructure [89].

2D Mater. 6 (2019) 042005

13

W Du et al

Although the structures studied theoretically are

still limited to small-diameter single-walled CNT-

graphene heterojunctions, significant new findings

have been obtained. One example is the opening of a

bandgap for a metallic CNT, while a semiconducting

CNT can be transformed into metallic under certain

heterostructure configurations.

It is well known that controlled synthesis of semi-

conducting CNTs for transistor applications is still

a challenge, while in the case of CNT-graphene het-

erostructures for interconnect applications, semicon-

ducting CNT is not needed. We suggest that future

theoretical study focuses on the transformation of

semiconducting CNT into metallic to support exper-

imental efforts in controlled synthesis. To bridge the

gap between theory and experiment, more theor-

etical studies on MWCNT-graphene heterostructures

should be initiated.

Most of the CNT-graphene heterostructures have

been synthesized by CVD methods, which are usually

adapted from the CNT growth recipes with careful

control of catalyst deposition and catalyst-substrate

interactions. Several works have reported TEM anal-

yses of the CNT-graphene interface in attempting to

reveal the C–C bonding across the interface [48, 60,

67, 70, 86, 123]. Thus far, the experimental findings, in

conjunction with atomistic models used in theoretical

calculations, are still a long way from being conclusive

on the interfacial atomic arrangements. Therefore,

novel techniques are needed to reveal detailed inter-

facial information. For example, the ratio of sp

2

/sp

3

bonding can be extracted from the measured density

of states, if an atomically clean CNT-graphene junc-

tion can be prepared for advanced TEM and STM anal-

yses. The latter poses a great challenge in experimental

study of this heterostructure, while overcoming such

challenge would yield enormous gain in understand-

ing the heterostructure.

Currently, the applications of CNT-graphene het-

erostructures in electronics, thermal interface mat-

erials, and electrochemistry have mainly focused on

macroscale properties, such as electrical and thermal

resistances. In the near future, with more detailed

theoretical investigations and controlled syntheses

of high-quality CNT-graphene heterostructures, we

hope that their superior electron and phonon trans-

port properties can be harnessed to build devices in the

nanoscale, and applications such as nano-transistors,

advanced-node on-chip interconnects, and thermal

interface materials can be realized.

Acknowledgments

This study is supported by National Natural Science

Foundation of China (Grant 11804102), the Science and

Technology Program of Guangzhou (201804010393,

201807010072), Fundamental Research Funds for the

Central Universities and the Key Laboratories Program

(614280104051709). Changjian Zhou would like to

acknowledge the support from Guangdong Pearl River

Youth Talent Recruitment Program.

ORCID iDs

Min Zhang https://orcid.org/0000-0002-2225-

8024

Changjian Zhou https://orcid.org/0000-0002-7156-

348X

References

[1] Kroto H W, Heath J R, O’Brien S C, Curl R F and Smalley R E

1985 C60: buckminsterfullerene Nature 318 162–3

[2] Georgakilas V, Perman J A, Tucek J and Zboril R 2015 Broad

family of carbon nanoallotropes: classification, chemistry, and

applications of fullerenes, carbon dots, nanotubes, graphene,

nanodiamonds, and combined superstructures Chem. Rev.

115 4744–822

[3] Povie G, Segawa Y, Nishihara T, Miyauchi Y and Itami K 2017

Synthesis of a carbon nanobelt Science 356 172–5

[4] De Volder M F L, Tawfick S H, Baughman R H and Hart A J

2013 Carbon nanotubes: present and future commercial

applications Science 339 535–9

[5] Ferrari A C et al 2015 Science and technology roadmap for

graphene, related two-dimensional crystals, and hybrid

systems Nanoscale 7 4598–810

[6] Zhang Y, Tang T-T, Girit C, Hao Z, Martin M C, Zettl A,

Crommie M F, Shen Y R and Wang F 2009 Direct observation

of a widely tunable bandgap in bilayer graphene Nature

459 820–3

[7] Yu Y-J, Zhao Y, Ryu S, Brus L E, Kim K S and Kim P 2009

Tuning the graphene work function by electric field effect

Nano Lett. 9 3430–4

[8] Chen C-W, Lee M-H and Clark S J 2004 Band gap modification

of single-walled carbon nanotube and boron nitride nanotube

under a transverse electric field Nanotechnology 15 1837–43

[9] Chiu Y H, Lai Y H, Ho J H, Chuu D S and Lin M F 2008

Electronic structure of a two-dimensional graphene

monolayer in a spatially modulated magnetic field: peierls

tight-binding model Phys. Rev. B 77 045407

[10] Jarillo-Herrero P, Kong J, van der Zant H S J, Dekker C,

Kouwenhoven L P and De Franceschi S 2005 Electronic

transport spectroscopy of carbon nanotubes in a magnetic

field Phys. Rev. Lett. 94 156802

[11] Chen S, Sun Z and Liu F 2016 Strain engineering of graphene: a

review Nanoscale 8 3207–17

[12] Naumis G G, Barraza-Lopez S, Oliva-Leyva M and Terrones H

2017 Electronic and optical properties of strained graphene

and other strained 2D materials: a review Rep. Prog. Phys.

80 096501

[13] Ni G-X, Yang H-Z, Ji W, Baeck S-J, Toh C-T, Ahn J-H,

Pereira V M and Özyilmaz B 2014 Tuning optical conductivity

of large-scale CVD graphene by strain engineering Adv. Mater.

26 1081–6

[14] Wang C, Takei K, Takahashi T and Javey A 2013 Carbon

nanotube electronics—moving forward Chem. Soc. Rev.

42 2592–609

[15] Avouris P 2010 Graphene: electronic and photonic properties

and devices Nano Lett. 10 4285–94

[16] Lu C-H, Yang H-H, Zhu C-L, Chen X and Chen G-N 2009 A

graphene platform for sensing biomolecules Angew. Chem.,

Int. Ed. 48 4785–7

[17] Tang X, Bansaruntip S, Nakayama N, Yenilmez E, Chang Y-L

and Wang Q 2006 Carbon nanotube DNA sensor and sensing

mechanism Nano Lett. 6 1632–6

[18] Navas H, Picher M, Andrieux-Ledier A, Fossard F, Michel T,

Kozawa A, Maruyama T, Anglaret E, Loiseau A and Jourdain V

2017 Unveiling the evolutions of nanotube diameter

distribution during the growth of single-walled carbon

nanotubes ACS Nano 11 3081–8

2D Mater. 6 (2019) 042005

14

W Du et al

[19] Mattevi C, Kim H and Chhowalla M 2011 A review of chemical

vapour deposition of graphene on copper J. Mater. Chem.

21 3324–34

[20] Hafizi R, Tersoff J and Perebeinos V 2017 Band structure and

contact resistance of carbon nanotubes deformed by a metal

contact Phys. Rev. Lett. 119 207701

[21] Jiang Y, Wang P and Lin L 2011 Characterizations of contact

and sheet resistances of vertically aligned carbon nanotube

forests with intrinsic bottom contacts Nanotechnology

22 365704

[22] Lim S C, Jang J H, Bae D J, Han G H, Lee S, Yeo I-S and Lee Y H

2009 Contact resistance between metal and carbon nanotube

interconnects: effect of work function and wettability Appl.

Phys. Lett. 95 264103

[23] Léonard F and Talin A A 2011 Electrical contacts to one-

and two-dimensional nanomaterials Nat. Nanotechnol.

6 773–83

[24] Wilhite P, Vyas A A, Tan J, Tan J, Yamada T, Wang P, Park J and

Yang C Y 2014 Metal–nanocarbon contacts Semicond. Sci.

Technol. 29 054006

[25] Matsuda Y, Deng W-Q and Goddard W A 2010 Contact

Resistance for ‘End-contacted’ metal–graphene and metal–

nanotube interfaces from quantum mechanics J. Phys. Chem.

C 114 17845–50

[26] Nagashio K, Nishimura T, Kita K and Toriumi A 2009 Metal/

graphene contact as a performance Killer of ultra-high

mobility graphene analysis of intrinsic mobility and contact

resistance 2009 IEEE Int. Electron Devices Meeting pp 1–4

[27] Jang K-T, Lee S-Y, Na S-K, Lee S-K, Baek J-M, You W-

K, Park O-H, Kim R-H, Oh H-S and Joo Y-C 2018

Electromigration characteristics and morphological evolution

of Cu interconnects on CVD Co and Ru Liners for 10 nm class

VLSI technology IEEE Electron Device Lett. 39 1050–3

[28] Ward J W, Nichols J, Stachowiak T B, Ngo Q and Egerton E J

2012 Reduction of CNT interconnect resistance for the

replacement of Cu for future technology nodes IEEE Trans.

Nanotechnol. 11 56–62

[29] Kreup F, Graham A P, Liebau M, Duesberg G S, Seidel R and

Unger E 2004 Carbon nanotubes for interconnect applications

IEDM Technical Digest. IEEE Int. Electron Devices Meeting pp

683–6

[30] Awano Y, Sato S, Nihei M, Sakai T, Ohno Y and Mizutani T

2010 Carbon nanotubes for VLSI: interconnect and transistor

applications Proc. IEEE 98 2015–31

[31] Graham A P et al 2005 How do carbon nanotubes fit into the

semiconductor roadmap? Appl. Phys. A 80 1141–51

[32] Vyas A A, Zhou C, Wilhite P, Wang P and Yang C Y 2016

Electrical properties of carbon nanotube via interconnects for

30 nm linewidth and beyond Microelectron. Reliab. 61 35–42

[33] Zhou C, Vyas A A, Wilhite P, Wang P, Chan M and Yang C Y

2015 Resistance determination for Sub-100 nm carbon

nanotube vias IEEE Electron Device Lett. 36 71–3

[34] Wu W, Krishnan S, Yamada T, Sun X, Wilhite P, Wu R, Li K and

Yang C Y 2009 Contact resistance in carbon nanostructure via

interconnects Appl. Phys. Lett. 94 163113

[35] van der Veen M H, Barbarin Y, Vereecke B, Sugiura M,

Kashiwagi Y, Cott D J, Huyghebaert C and Tökei Z 2013

Electrical improvement of CNT contacts with Cu damascene

top metallization 2013 IEEE Int. Interconnect Technology Conf.

pp 1–3

[36] Zhu Y et al 2012 A seamless three-dimensional carbon

nanotube graphene hybrid material Nat. Commun. 3 1225

[37] El-Kady M F, Strong V, Dubin S and Kaner R B 2012 Laser

scribing of high-performance and flexible graphene-based

electrochemical capacitors Science 335 1326–30

[38] Yen M-Y, Hsiao M-C, Liao S-H, Liu P-I, Tsai H-M, Ma C-C M,

Pu N-W and Ger M-D 2011 Preparation of graphene/multi-

walled carbon nanotube hybrid and its use as photoanodes of

dye-sensitized solar cells Carbon 49 3597–606

[39] Kaempgen M, Chan C K, Ma J, Cui Y and Gruner G 2009

Printable thin film supercapacitors using single-walled carbon

nanotubes, Nano Lett. 9 1872–6

[40] Li D, Müller M B, Gilje S, Kaner R B and Wallace G G 2008

Processable aqueous dispersions of graphene nanosheets Nat.

Nanotechnol. 3 101–5

[41] Saleh N B, Pfefferle L D and Elimelech M 2008 Aggregation

kinetics of multiwalled carbon nanotubes in aquatic systems:

measurements and environmental implications Environ. Sci.

Technol. 42 7963–9

[42] Kim Y S, Kumar K, Fisher F T and Yang E H 2012 Out-of-plane

growth of CNTs on graphene for supercapacitor applications

Nanotechnology 23 015301

[43] You B, Wang L, Yao L and Yang J 2013 Three dimensional

N-doped graphene–CNT networks for supercapacitor Chem.

Commun. 49 5016

[44] Wang J, Ma F, Liang W and Sun M 2017 Electrical properties

and applications of graphene, hexagonal boron nitride

(h-BN), and graphene/h-BN heterostructures Mater. Today

Phys. 2 6–34

[45] Wang J, Mu X, Wang X, Wang N, Ma F, Liang W and Sun M

2018 The thermal and thermoelectric properties of in-plane

C-BN hybrid structures and graphene/h-BN van der Waals

heterostructures Mater. Today Phys. 5 29–57

[46] Wang J, Ma F, Liang W, Wang R and Sun M 2017 Optical,

photonic and optoelectronic properties of graphene, h-BN

and their hybrid materials Nanophotonics 6 943–76

[47] Wang J, Xu X, Mu X, Ma F and Sun M 2017 Magnetics and

spintronics on two-dimensional composite materials of

graphene/hexagonal boron nitride Mater. Today Phys.

3 93–117

[48] Ghosh K, Ranjan N, Verma Y K and Tan C S 2016 Graphene–

CNT hetero-structure for next generation interconnects RSC

Adv. 6 53054–61

[49] Novaes F D, Rurali R and Ordejón P 2010 Electronic transport

between graphene layers covalently connected by carbon

nanotubes ACS Nano 4 7596–602

[50] Lee D H, Kim J E, Han T H, Hwang J W, Jeon S, Choi S Y,

Hong S H, Lee W J, Ruoff R S and Kim S O 2010 Versatile

carbon hybrid films composed of vertical carbon nanotubes

grown on mechanically compliant graphene films Adv. Mater.

22 1247–52

[51] Qin H, Sun Y, Liu J Z and Liu Y 2017 Enhanced in-plane

mechanical properties of nanoporous graphene-carbon

nanotube network J. Appl. Phys. 121 215104

[52] Fan Z, Yan J, Zhi L, Zhang Q, Wei T, Feng J, Zhang M, Qian W

and Wei F 2010 A three-dimensional carbon nanotube/

graphene sandwich and its application as electrode in

supercapacitors Adv. Mater. 22 3723–8

[53] Tessonnier J-P and Su D S 2011 Recent progress on the growth

mechanism of carbon nanotubes: a review ChemSusChem

4 824–47

[54] Bae S et al 2010 Roll-to-roll production of 30-inch graphene

films for transparent electrodes Nat. Nanotechnol. 5 574

[55] Wu S, Shi E, Yang Y, Xu W, Li X and Cao A 2015 Direct

fabrication of carbon nanotube-graphene hybrid films by a

blown bubble method Nano Res. 8 1746–54

[56] Shi E, Li H, Yang L, Hou J, Li Y, Li L, Cao A and Fang Y 2015

Carbon nanotube network embroidered graphene films for

monolithic all-carbon electronics Adv. Mater. 27 682–8

[57] Hunley D P, Johnson S L, Stieha J K, Sundararajan A,

Meacham A T, Ivanov I N and Strachan D R 2011

Crystallographically aligned carbon nanotubes grown on few-

layer graphene films ACS Nano 5 6403–9

[58] Yan Z et al 2014 Rebar graphene ACS Nano 8 5061–8

[59] Maarouf A A, Kasry A, Chandra B and Martyna G J 2016 A

graphene–carbon nanotube hybrid material for photovoltaic

applications Carbon 102 74–80

[60] Choi H, Kim H, Hwang S, Kang M, Jung D-W and Jeon M

2011 Electrochemical electrodes of graphene-based carbon

nanotubes grown by chemical vapor deposition Scr. Mater.

64 601–4

[61] Li X, Zhu G and Xu Z 2012 Nitrogen-doped carbon nanotube

arrays grown on graphene substrate Thin Solid Films

520 1959–64

2D Mater. 6 (2019) 042005

15

W Du et al

[62] Nguyen D D, Tai N H, Chen S Y and Chueh Y L 2012

Controlled growth of carbon nanotube-graphene hybrid

materials for flexible and transparent conductors and electron

field emitters Nanoscale 4 632–8

[63] Kumar K, Kim Y-S, Li X, Ding J, Fisher F T and Yang E-H

2013 Chemical vapor deposition of carbon nanotubes

on monolayer graphene substrates: reduced etching via

suppressed catalytic hydrogenation using C

2

H

4

Chem. Mater.

25 3874–9

[64] Rao R, Chen G, Arava L M, Kalaga K, Ishigami M, Heinz T F,

Ajayan P M and Harutyunyan A R 2013 Graphene as an

atomically thin interface for growth of vertically aligned

carbon nanotubes Sci. Rep. 3 1891

[65] Ryu J H, Lee G J, Kim W S, Lim H E, Mativenga M, Park K C

and Park H K 2014 All-carbon electrode consisting of carbon

nanotubes on graphite foil for flexible electrochemical

applications Materials 7 1975–83

[66] Ramos R, Fournier A, Fayolle M, Dijon J, Murray C P and

McKenna J 2016 Nanocarbon interconnects combining

vertical CNT interconnects and horizontal graphene lines 2016

IEEE Int. Interconnect Technology Conf./Advanced Metallization

Conf. pp 48–50

[67] Kondo D, Sato S and Awano Y 2008 Self-organization of novel

carbon composite structure: graphene multi-layers combined

perpendicularly with aligned carbon nanotubes Appl. Phys.

Express 1 074003

[68] Jousseaume V, Cuzzocrea J, Bernier N and Renard V T 2011

Few graphene layers/carbon nanotube composites grown at

complementary-metal-oxide-semiconductor compatible

temperature Appl. Phys. Lett. 98 123103

[69] Choi J W, Youn S K and Park H G 2013 Carbon

micronymphaea: graphene on vertically aligned carbon

nanotubes J. Nanomater. 2013 1–7

[70] Salvatierra R V, Zakhidov D, Sha J, Kim N D, Lee S K, Raji A O,

Zhao N and Tour J M 2017 Graphene carbon nanotube carpets

grown using binary catalysts for high-performance lithium-

ion capacitors ACS Nano 11 2724–33

[71] Dimitrakakis G K, Tylianakis E and Froudakis G E 2008

Pillared graphene: a new 3D network nanostructure for

enhanced hydrogen storage Nano Lett. 8 3166–70

[72] Gao M, Huang Z L, Zeng B, Pan T S, Zhang Y, Peng H B and

Lin Y 2015 Carbon nanotube-graphene junctions studied by

impedance spectra Appl. Phys. Lett. 106 051601

[73] Du F, Yu D, Dai L, Ganguli S, Varshney V and Roy A K 2011

Preparation of tunable 3D pillared carbon nanotube–

graphene networks for high-performance capacitance Chem.

Mater. 23 4810–6

[74] Chen J, Walther J H and Koumoutsakos P 2015 Covalently

bonded graphene-carbon nanotube hybrid for high-

performance thermal interfaces Adv. Funct. Mater. 25 7539–45

[75] Varshney V, Patnaik S S, Roy A K, Froudakis G and Farmer B L

2010 Modeling of thermal transport in pillared-graphene

architectures ACS Nano 4 1153–61

[76] Jiang J, Li Y, Gao C, Kim N D, Fan X, Wang G, Peng Z,

Hauge R H and Tour J M 2016 Growing carbon nanotubes

from both sides of graphene ACS Appl. Mater. Interfaces

8 7356–62

[77] Dupuis A 2005 The catalyst in the CCVD of carbon

nanotubes—a review Prog. Mater. Sci. 50 929–61

[78] Muñoz R and Gómez-Aleixandre C 2013 Review of CVD

synthesis of graphene Chemical Vapor Depos. 19 297–322

[79] Zhang Y, Zhang L and Zhou C 2013 Review of chemical vapor

deposition of graphene and related applications Acc. Chem.

Res. 46 2329–39

[80] Van Chuc N, Thanh C T, Van Tu N, Phuong V T Q, Thang P V

and Thanh Tam N T 2015 A simple approach to the fabrication

of graphene-carbon nanotube hybrid films on copper

substrate by chemical vapor deposition J. Mater. Sci. Technol.

31 479–83

[81] Lin X, Liu P, Wei Y, Li Q, Wang J, Wu Y, Feng C, Zhang L, Fan S

and Jiang K 2013 Development of an ultra-thin film comprised

of a graphene membrane and carbon nanotube vein support

Nat. Commun. 4 2920

[82] Engels S, Weber P, Terres B, Dauber J, Meyer C, Volk C,

Trellenkamp S, Wichmann U and Stampfer C 2013

Fabrication of coupled graphene-nanotube quantum devices

Nanotechnology 24 035204

[83] Matsumoto T and Saito S 2002 Geometric and electronic

structure of new carbon-network materials: nanotube array

on graphite sheet J. Phys. Soc. Japan 71 2765–70

[84] Dang V T, Nguyen D D, Cao T T, Le P H, Tran D L, Phan N M

and Nguyen V C 2016 Recent trends in preparation and

application of carbon nanotube–graphene hybrid thin films

Adv. Nat. Sci.: Nanosci. Nanotechnol. 7 033002

[85] Ping L, Hou P X, Liu C, Li J, Zhao Y, Zhang F, Ma C, Tai K,

Cong H and Cheng H M 2017 Surface-restrained growth

of vertically aligned carbon nanotube arrays with excellent

thermal transport performance Nanoscale 9 8213–9

[86] Rout C S, Kumar A, Fisher T S, Gautam U K, Bando Y and

Golberg D 2012 Synthesis of chemically bonded CNT–

graphene heterostructure arrays RSC Adv. 2 8250

[87] Yan Z et al 2013 Three-dimensional metal–graphene–

nanotube multifunctional hybrid materials ACS Nano

7 58–64

[88] Jyothirmayee Aravind S S, Eswaraiah V and Ramaprabhu S

2011 Facile synthesis of one dimensional graphene wrapped

carbon nanotube composites by chemical vapour deposition

J. Mater. Chem. 21 15179

[89] Zhou C, Senegor R, Baron Z, Chen Y, Raju S, Vyas A A,

Chan M, Chai Y and Yang C Y 2017 Synthesis and interface

characterization of CNTs on graphene Nanotechnology

28 054007

[90] Zhao M-Q, Liu X-F, Zhang Q, Tian G-L, Huang J-Q, Zhu W

and Wei F 2012 Graphene/single-walled carbon nanotube

hybrids: one-step catalytic growth and applications for high-

rate Li–S batteries ACS Nano 6 10759–69

[91] Tian G-L, Zhao M-Q, Yu D, Kong X-Y, Huang J-Q, Zhang Q

and Wei F 2014 Nitrogen-doped graphene/carbon nanotube

hybrids: in situ formation on bifunctional catalysts and

their superior electrocatalytic activity for oxygen evolution/

reduction reaction Small 10 2251–9

[92]

Xue Y, Ding Y, Niu J, Xia Z, Roy A, Chen H, Qu J, Wang Z L

and Dai L 2015 Rationally designed graphene-nanotube 3D

architectures with a seamless nodal junction for efficient

energy conversion and storage Sci. Adv. 1 2375–48

[93] Ho Y H, Chiu Y H, Lu J M and Lin M F 2010 Low-energy

electronic structures of nanotube–graphene hybrid carbon

systems Physica E 42 744–7

[94] Cook B G, French W R and Varga K 2012 Electron transport

properties of carbon nanotube–graphene contacts Appl. Phys.

Lett. 101 153501

[95] Robert P T and Danneau R 2014 Charge distribution of

metallic single walled carbon nanotube–graphene junctions

New J. Phys. 16 013019

[96] Chai Y, Hazeghi A, Takei K, Chen H-Y, Chan P C H, Javey A

and Wong H S P 2012 Low-resistance electrical contact to

carbon nanotubes with graphitic interfacial layer IEEE Trans.

Electron Devices 59 12–9

[97] Gangavarapu P R Y, Lokesh P C, Bhat K N and Naik A K 2017

Graphene electrodes as barrier-free contacts for carbon

nanotube field-effect transistors IEEE Trans. Electron Devices

64 4335–9

[98] Ivanovskaya V V, Zobelli A, Wagner P, Heggie M I,

Briddon P R, Rayson M J and Ewels C P 2011 Low-energy

termination of graphene edges via the formation of narrow

nanotubes Phys. Rev. Lett. 107 065502

[99] Akhukov M A, Yuan S, Fasolino A and Katsnelson M I

2012 Electronic, magnetic and transport properties of

graphene ribbons terminated by nanotubes New J. Phys.

14 123012

[100] Artyukh A A, Chernozatonskii L A and Sorokin P B 2010

Mechanical and electronic properties of carbon nanotube-

graphene compounds Phys. Status Solidi b 247 2927–30

[101] Baowan D, Cox B J and Hill J M 2007 Two least squares

analyses of bond lengths and bond angles for the joining of

carbon nanotubes to graphenes Carbon 45 2972–80

2D Mater. 6 (2019) 042005

16

W Du et al

[102] Baowan D, Cox B J, Thamwattana N and Hill J M 2009

Two minimisation approximations for joining carbon

nanostructures IUTAM Symp. on Modelling Nanomaterials

and Nanosystems pp 109–21

[103] Kroto H W 1987 The stability of the fullerenes Cn, with

n = 24, 28, 32, 36, 50, 60 and 70 Nature 329 529–31

[104] Terrones H and Mackay A L 1992 The geometry of

hypothetical curved graphite structures Carbon 30 1251–60

[105] Terrones H and Terrones M 2003 Curved nanostructured

materials New J. Phys. 5 126

[106] Ebbesen T W and Takada T 1995 Topological and SP3 defect

structures in nanotubes Carbon 33 973–8

[107] Yang N, Yang D, Chen L, Liu D, Cai M and Fan X 2017 A

first-principle theoretical study of mechanical and electronic

properties in graphene single-walled carbon nanotube

junctions Materials 10 1300

[108] Taylor J, Guo H and Wang J 2001 Ab initio modeling of

quantum transport properties of molecular electronic devices

Phys. Rev. B 63 245407

[109] Soler J M, Artacho E, Gale J D, García A, Junquera J, Ordejón P

and Sánchez-Portal D 2002 The SIESTA method forab

initioorder-N materials simulation J. Phys.: Condens. Matter

14 2745–79

[110] Hanwell M D, Curtis D E, Lonie D C, Vandermeersch T,

Zurek E and Hutchison G R 2012 Avogadro: an advanced

semantic chemical editor, visualization, and analysis platform

J. Cheminform. 4 17

[111] Mao Y and Zhong J 2009 The computational design of

junctions by carbon nanotube insertion into a graphene

matrix New J. Phys. 11 093002

[112] Huang H, Liu C H, Wu Y and Fan S 2005 Aligned carbon

nanotube composite films for thermal management Adv.

Mater. 17 1652–6

[113] Zhang Z, Kutana A, Roy A and Yakobson B I 2017

Nanochimneys: topology and thermal conductance of

3D nanotube–graphene cone junctions J. Phys. Chem. C

121 1257–62

[114] Chen J, Walther J H and Koumoutsakos P 2016

Ultrafast cooling by covalently bonded graphene-carbon

nanotube hybrid immersed in water Nanotechnology

27 465705

[115] Shi J, Dong Y, Fisher T and Ruan X 2015 Thermal transport

across carbon nanotube-graphene covalent and van der Waals

junctions J. Appl. Phys. 118 044302